Welcome to Dongguan Great Machinery Co., Ltd.!

06.11 16:01

Driving Manufacturing Excellence: The Power of Advanced Packaging Solutions

Driving Manufacturing Excellence: The Power of Advanced Packaging Solutions

In today's fast-paced manufacturing environment, driving excellence is essential for maintaining competitiveness and meeting consumer demands. From the materials utilized to the machinery employed, every aspect of packaging plays a vital role in ensuring the timely delivery of high-quality products to markets worldwide.

Sealants, silicones, and polyurethanes are versatile materials that serve as the backbone of modern manufacturing. In the construction industry, sealants provide weatherproofing and sealing joints, ensuring structural integrity and energy efficiency. Automotive manufacturers rely on silicones for high-performance bonding solutions, contributing to vehicle safety and longevity. In electronics, polyurethanes offer insulation and protection for sensitive electronic components, safeguarding against moisture and environmental hazards. In the healthcare sector, medical-grade silicones are used in the production of medical devices and implants, providing biocompatibility and durability.

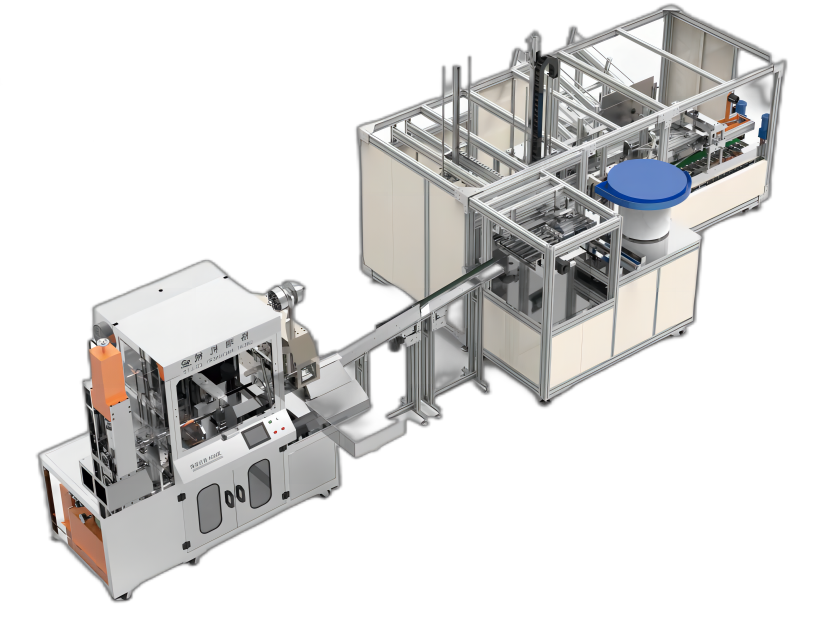

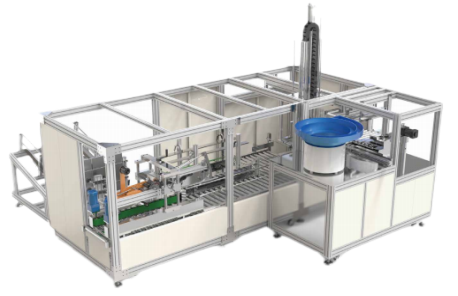

Additionally, innovative packaging machinery such as the Automatic Cartridge Pack Packaging and Palletizing Production Line has revolutionized manufacturing operations. This state-of-the-art system integrates cutting-edge technology for automatic bottle loading, tail plug loading, volume measurement, servo glue cutting, exhaust plug cap, and coding. With a production capacity exceeding 2 tons per hour and a packaging speed of over 200 boxes, this system sets a new standard for efficiency in the industry.

The adoption of advanced packaging solutions, including the Automatic Cartridge Pack Packaging and Palletizing Production Line, offers numerous benefits for factories and industries. Improved productivity is achieved through streamlined processes and increased throughput, allowing manufacturers to meet growing demand effectively. Enhanced quality control ensures consistent product quality and compliance with regulatory standards, safeguarding brand reputation and consumer trust. Cost savings are realized through reduced labor costs, minimized material wastage, and lower energy consumption, contributing to improved profitability. Market competitiveness is strengthened as manufacturers can respond quickly to market demands and offer customized packaging solutions to meet diverse customer needs. Environmental responsibility is demonstrated through the adoption of sustainable practices, including the use of eco-friendly materials and energy-efficient machinery, aligning with consumer preferences for environmentally conscious products.

Collaboration among manufacturers, suppliers, and technology providers is essential for driving innovation in the packaging industry. Research and development efforts focus on creating new materials and technologies that address emerging market trends and challenges, ensuring continued progress and competitiveness. Technical support and adherence to industry standards are crucial for successful implementation and operation of packaging solutions, providing manufacturers with the necessary guidance and assurance to achieve optimal results.

In conclusion, driving manufacturing excellence requires leveraging the power of advanced packaging solutions, such as the Automatic Cartridge Pack Packaging and Palletizing Production Line. By embracing versatile materials, innovative machinery, and collaborative partnerships, manufacturers can optimize processes, improve productivity, and meet market demands effectively, ensuring long-term success and competitiveness in today's dynamic business environment.

Related News

How to Choose Cartridge-Pack Sealant Packaging Equipment

🔄𝐄𝐱𝐩𝐞𝐫𝐭 𝐬𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬 𝐟𝐨𝐫 𝐂𝐚𝐫𝐭𝐫𝐢𝐝𝐠-𝐏𝐚𝐜𝐤 𝐬𝐞𝐚𝐥𝐚𝐧𝐭 𝐰𝐢𝐭𝐡 𝐆𝐫𝐞𝐚𝐭 𝐌𝐚𝐜𝐡𝐢𝐧𝐞𝐫𝐲 At 𝐆𝐫𝐞𝐚𝐭 𝐌𝐚𝐜𝐡𝐢𝐧𝐞𝐫𝐲, we understand that the demand for precision and efficiency in packaging equipment has never been greater.Whether you're working with 𝐟𝐥𝐨𝐰𝐚𝐛𝐥𝐞 𝐬𝐢𝐥𝐢𝐜𝐨𝐧𝐞 𝐚𝐧𝐝 𝐩𝐨𝐥𝐲𝐮𝐫𝐞𝐭𝐡𝐚𝐧𝐞 𝐬𝐞𝐚𝐥𝐚𝐧𝐭𝐬 or 𝐡𝐢𝐠𝐡-𝐯𝐢𝐬𝐜𝐨𝐬𝐢𝐭𝐲 𝐀𝐁 𝐬𝐞𝐚𝐥𝐚𝐧𝐭𝐬, our advanced technology ensures 𝐡𝐢𝐠𝐡-𝐩𝐫𝐞𝐜𝐢𝐬𝐢𝐨𝐧 𝐟𝐢𝐥𝐥𝐢𝐧𝐠, 𝐦𝐢𝐧𝐢𝐦𝐚𝐥 𝐰𝐚𝐬𝐭𝐞, and enhanced production efficiency. 🌀𝐊𝐞𝐲 𝐅𝐞𝐚𝐭𝐮𝐫𝐞𝐬: 🔹𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐝 𝐀𝐮𝐭𝐨𝐦𝐚𝐭𝐢𝐨𝐧: From semi-automatic systems to fully automated lines that optimize both efficiency and cost 🔹𝐓𝐚𝐢𝐥𝐨𝐫𝐞𝐝 𝐒𝐨𝐥𝐮𝐭𝐢𝐨𝐧𝐬: Custom designs to meet your specific packaging needs, ensuring product consistency and high-quality standards

Read moreChoosing the Right Sealing Adhesive Filling Equipment: Efficient Solutions from Great Machinery

🚀 𝐇𝐨𝐰 𝐭𝐨 𝐂𝐡𝐨𝐨𝐬𝐞 𝐭𝐡𝐞 𝐑𝐢𝐠𝐡𝐭 𝐒𝐞𝐚𝐥𝐚𝐧𝐭 𝐅𝐢𝐥𝐥𝐢𝐧𝐠 𝐄𝐪𝐮𝐢𝐩𝐦𝐞𝐧𝐭? As the adhesive and sealant market continues to expand, selecting the right filling equipment is critical for 𝐛𝐨𝐨𝐬𝐭𝐢𝐧𝐠 𝐩𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧 𝐞𝐟𝐟𝐢𝐜𝐢𝐞𝐧𝐜𝐲 𝐚𝐧𝐝 𝐞𝐧𝐬𝐮𝐫𝐢𝐧𝐠 𝐩𝐫𝐨𝐝𝐮𝐜𝐭 𝐪𝐮𝐚𝐥𝐢𝐭𝐲. Let Great Machinery provide you with efficient solutions to know how our report can help streamline your business. 🎯𝐈𝐧 𝐨𝐮𝐫 𝐥𝐚𝐭𝐞𝐬𝐭 𝐚𝐫𝐭𝐢𝐜𝐥𝐞, 𝐰𝐞 𝐞𝐱𝐩𝐥𝐨𝐫𝐞: 🔹The different types of sealants and their applications; 🔹How viscosity and density influence your equipment choice; 🔹The best filling equipment configurations for various production lines. Whether you’re dealing with low-viscosity silicone or high-viscosity polyurethane, we have the perfect solution for you. Discover how our 𝐯𝐞𝐫𝐭𝐢𝐜𝐚𝐥, 𝐡𝐨𝐫𝐢𝐳𝐨𝐧𝐭𝐚𝐥, 𝐚𝐧𝐝 𝐚𝐮𝐭𝐨𝐦𝐚𝐭𝐞𝐝 𝐬𝐲𝐬𝐭𝐞𝐦𝐬 can enhance your production!

Read moreEnsuring Excellence in Sealant Production: Great Machinery Empowering the Global Adhesive Industry

As demand for high-performance sealants rises across industries like construction and aerospace, efficient production solutions are vital. In our latest article, discover how Great Machinery leads in sealant packaging and filling equipment, providing cutting-edge technology that enhances production, boosts efficiency, and ensures precision. From hydraulic machines to automated packing systems, we offer expertise to meet the global adhesive industry's evolving needs.

Read more